Top 10+ Advantages of WashBOT Transformer 3XM

1. The Most Flexible Wash System Ever*

The PATENT PENDING WashBOT research design effort started in 2006. We endeavored to build a machine that would provide the ultimate customer experience and would be flexible enough to resolve the issue of touch free/ friction preferential washing.

WashBOT is not another friction wash system with high pressure nozzles; this is truly a complete friction or completely touch free machine. Looking in the bay- you will not see a machine with brushes hanging off of it to intimidate potential touch free customers.

YOUR CUSTOMERS HAVE A CLEAR CHOICE!

It picks up and drops off the wash tools it needs. Additionally, once WashBOT drops off the wash tools, it has unobstructed freedom to perform many rinses, triple foam, powerfoam, high pressure spot free, clear coat conditioner, RoboDry, and other operations…

INCREASE YOUR CUSTOMER BASE WITH THE SOFT-TOUCH OR TOUCH FREE PREFERENCED CUSTOMERS!

*soft touch option sold separately

- SOFT TOUCH

- TOUCH FREE

2. MARKETABLE TECHNOLOGY

Technology that is not only functional, but also that gives the customers a show. This is more than lights, triplefoam, or some other color enhanced display (although it has those too). The entire machine is the customer interaction.

PATENT PENDING Power Foamer ™ system ultimate in foam show and even application on the vehicle, to apply sealant, waxes, soaps etc. CTA Power Foamer ™ for an additional upgrade!

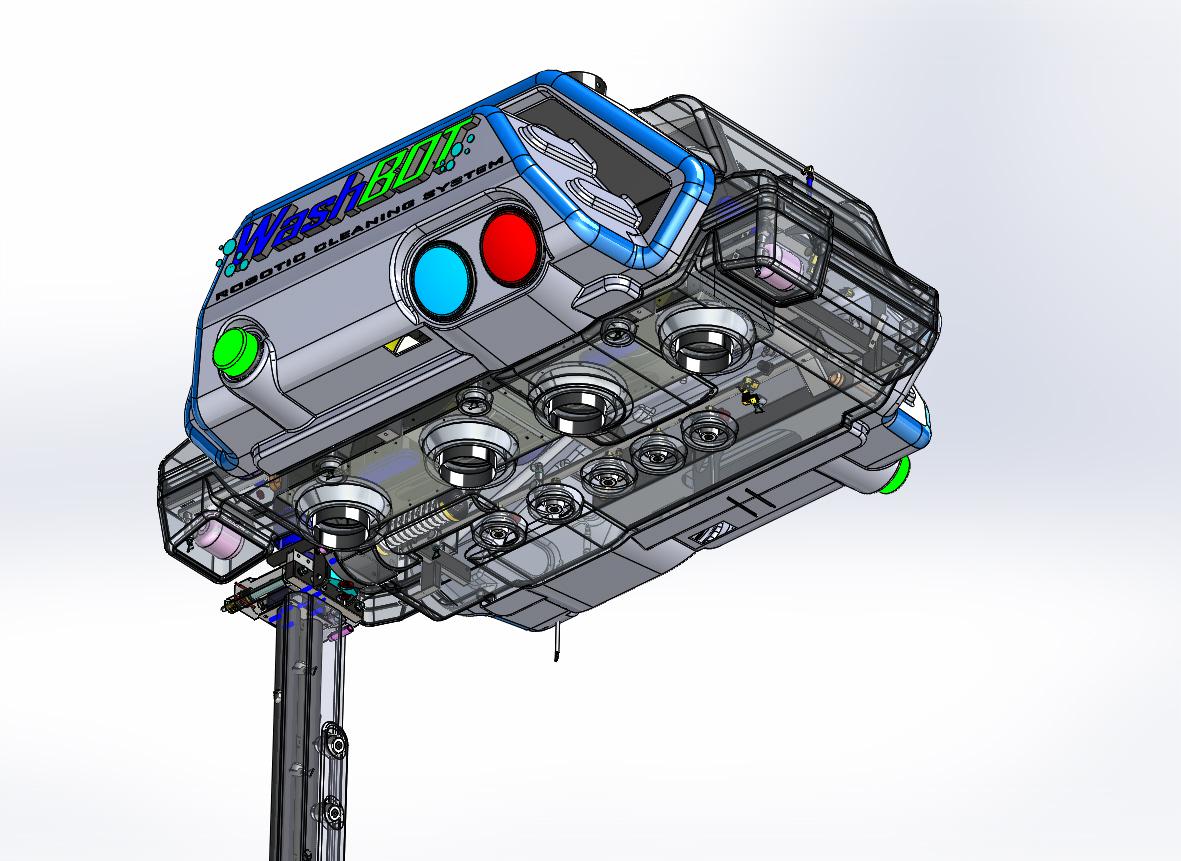

3. “BULLET PROOF” DESIGN

PX Machines has taken the stand that we are not in the parts business, nor do we want to be. Our objective is to build machines that work well and our customers absolutely love. We endeavor to use common off the shelf parts as much as possible, however for the sake of the best performance we will use custom, robust materials and parts as required.

Track/ machine frame- our 304 Stainless Steel frames are not saw cut. Every feature is CNC cut using the most advanced technology. Our frame features are cut +/-.003” from one end to the other using robots!

IP 67 Waterproof Industrial “Smart Motors”, Robust Industrial Controller, with built in positioning feedback.

No Lubrication points– all stainless steel sealed ball bearings. Stainless steel pulleys, high performance timing system..Industrial Robotics Planetary Gearboxes- higher efficiency and reliability than worm gearboxes commonly used. Gearboxes come with 5 YEAR Manufacturers Warranty.

- Touch-free configuration only uses three travel motors total, add just one for soft-touch.

- All positioning motors and gearboxes are the same part to minimize inventory.

- No travel positioning proximity switches to worry about constant adjustment/damage

- No drive wheels, ultra robust timing belting for positioning.

- Water screens for all nozzles to prevent clogging.

PATENT PENDING MicroPump ™ Single Pump Design only requiring 1/2” high pressure hose to the machine. Limited amount of solenoids and chem injectors required.

PATENT PENDING Speed Chain ™ has limited power and water conductors feeding the machine.

4. BETTER WASH PROCESS

For touch-free washing, cleaning solution is applied to the vehicle before any high pressure washing takes place. Not even the rocker panel, allowing the chemical best opportunity to do the best job.

We utilize only the highest quality 0 degree turbonozzles on the market, and size up the vehicle on all four sides for maximum impingement.

BETTER SOLUTION

BETTER IMPACT

- Mirror and pickup back window washing capability.

- One of the few In-Bay Automatics with CTA.

- Capable of friction and high pressure combination washing to provide the ultimate in cleaning.

5. HIGH SPEED WASHING

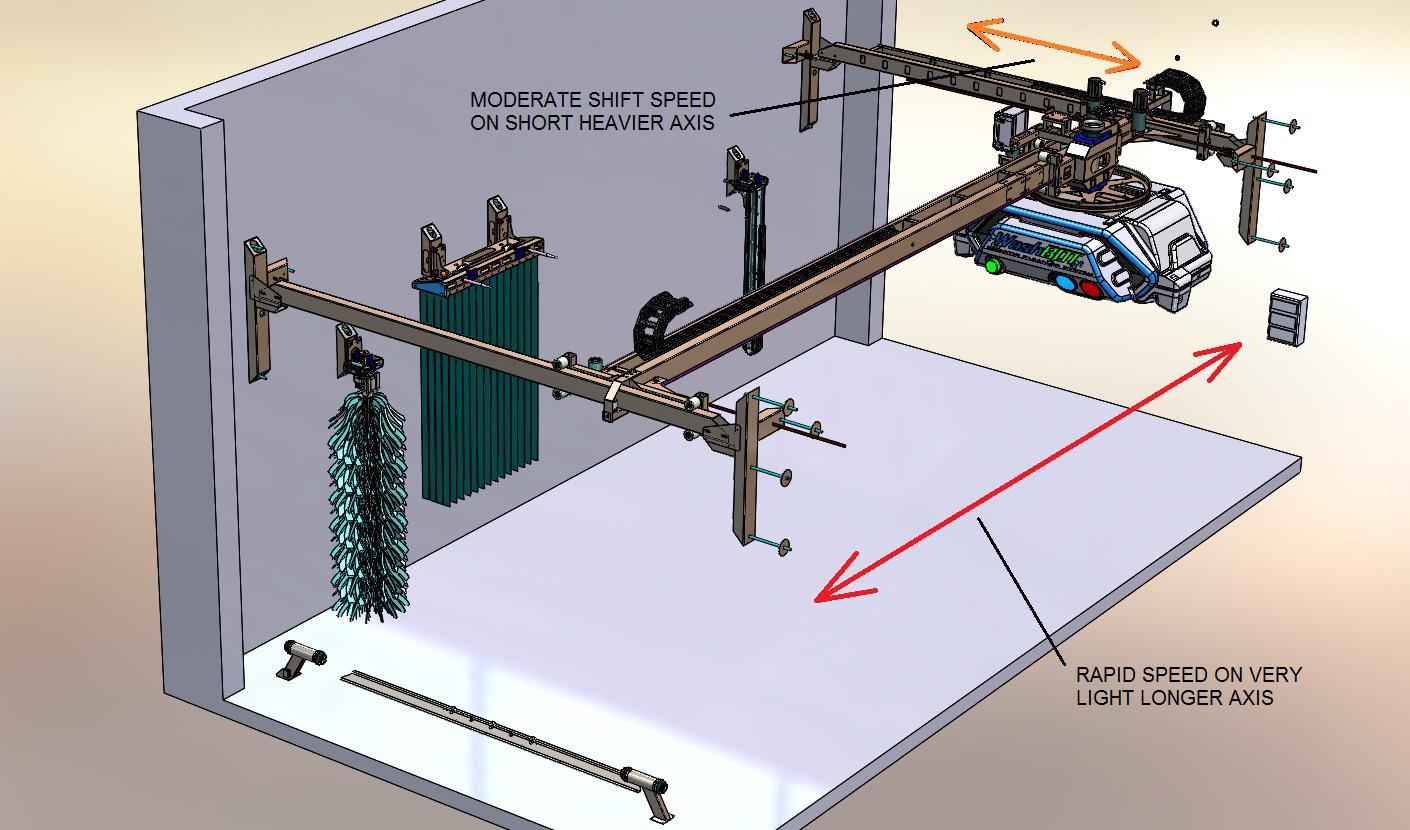

PATENT PENDING Accelerator ™ high speed track system- Unique track design that allows the lightweight WashBOT to reciprocate very quickly on the monorail beam the bay length.

- Power Foamer ™ puts down complete layer of thick foam on the vehicle in 4 seconds!

- CTA Power Foamer ™ (off-board) puts foam on the tires in 1 second!

- Power Presoak- high speed presoak application, larger volume quicker application.

- High pressure/ high speed spot free- WashBOT rotates 180degrees and angles the on-board rinse nozzles in each direction.

High performance, industrial robotic servomotors and advanced controls run WashBOT to the maximum capability.

6. LOW OWNERSHIP COST

Low water consumption at 15 GPM for high pressure washing

Low power consumption with 10 HP soft start pump motor and 20 HP high efficiency soft start blower motors.

Lower installation costs- Machine three phase power is hooked up to the off-board electrical panel. All power is distributed out from there with 24 VDC control power, including the lights to limit Class 1 power electrical installation. All mapping sensors are located on-board, not needing wall installation.

7. VEHICLE POSITIONING TECHNOLOGY

PATENT PENDING 3D RoboScan ™

Ability to locate the vehicle in almost any position in the bay and wash it. This means no city markers, guide rails, etc…to try to get the customer centered in the bay.

CUSTOMER EASE OF USE, EASY IN AND OUT.

Only TWO Sensors required to instruct the driver to stop, back up, pull forward, and measure the vehicle’s four sides and the top vehicle contour. Unless they hit the wall, you can probably get them washed.

8. EFFICIENT AND ACCURATE DRYING

RoboDry ™

WashBOT has the ability to line up on-board blowers directly over the vehicle target surface. This means rather than using 30 HP blowing down the entire potential width of the bay, it locates exactly where the vehicle is and dries accordingly.

No drying of floors.

ACCURATE, ENERGY SAVING, DRYING POWER.

9. NO REQUIRED AIR COMPRESSOR

PATENT PENDING TECHNOLOGY

One of our latest advancements is an automatic not requiring the installation or upkeep of compressed air without sacrificing simplicity or foam quality. No need to install power for, not needing an air compressor.

10. REMOTE DIAGNOSTICS

One of the most advanced and robust motion PAC controllers in the Automation and Robotics industry with the capability to do far more than the typical PLC wash controller. This is how WashBOT is controlled so well.

Remote diagnostics allows the ability to remote rest WashBOT.

11. SELF CLEANING BAY OPTION – COMING SOON!

PATENT PENDING TECHNOLOGY

Depending on the size of the bay, WashBOT can even wash down the bay walls and floor.

During a predetermined maintenance time, WashBOT goes through a maintenance routine where it picks up an auxiliary wash bar and washes the walls and corners of the bay all the way around the bay and then from the floor perimeter into the center drain.

- Great for glass buildings, or bays where there is a lot of glass needing to stay clean.

- No additional plumbing required.

Specification Page Coming

Check Out Other Reasons WashBOT 3XM Is Right For You

Contact us for a personalized quote

-The PX Machines Design Team